Invisible Heat, Visible Savings: How SenseLive’s Wireless Busbar Monitoring Shields Switchgear, Malls & Hospitals

Summery :

Busbar hot-spots are silent saboteurs that trigger switchgear fires, unplanned shutdowns and eye-watering downtime costs in malls, hospitals and panel-building factories. Periodic IR scans can miss the earliest signs of trouble; only continuous, wireless thermal monitoring catches temperature drift in real time.

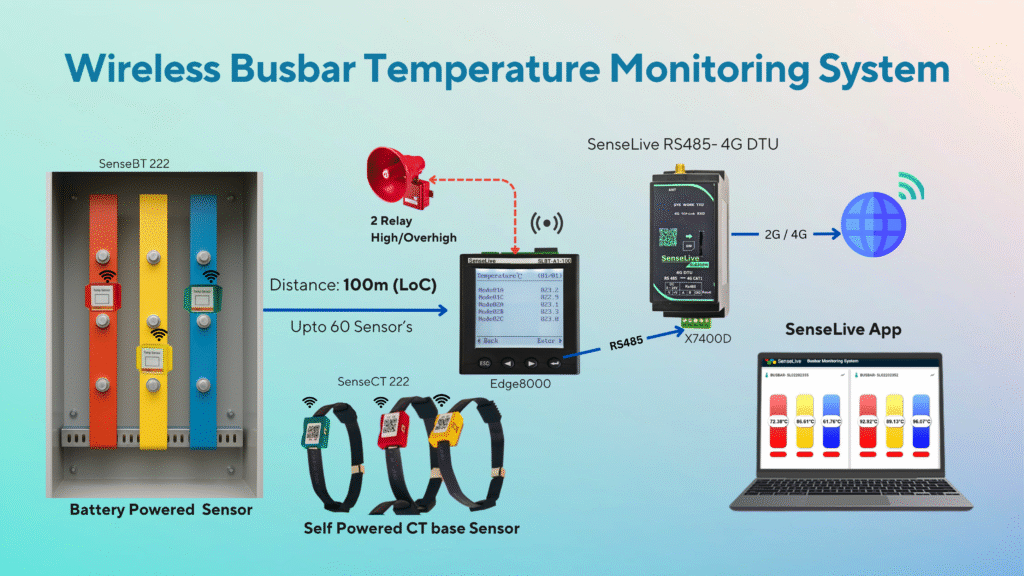

SenseLive’s trio — the Edge8000 controller, SenseBT-222 battery-powered sensor and SenseCT-222 CT-powered sensor — forms a retrofit, maintenance-free safety net that keeps critical power flowing and budgets intact.

Time = ₹ Money: What a Hot Busbar Really Costs in India

- 🏥 Hospitals

A single power-chain glitch that freezes OTs and shifts ICUs to generators can drain ₹ 6–7 lakh every minute in lost procedures, staff overtime and recovery overheads.

nettechconsultants.com - 🛍️ Retail & Malls

During Maharashtra’s 2021 shutdown, shopping-centre operators reported ₹ 40,000 crore in lost takings for the month—almost ₹ 90 lakh per minute of blacked-out business.

m.economictimes.com - 🏭 Manufacturing Plants

ABB’s 2023 “Value of Reliability” survey puts the hit from an unplanned trip at ₹ 70 lakh an hour for Indian factories—about ₹ 1.2 lakh every 60 seconds that production stands still.

new.abb.com

A busbar hot-spot can spark exactly these scenarios. SenseLive’s always-on, wireless monitoring lets you spot the temperature rise before the rupees start flying.

🔍 Why Periodic Thermography Falls Short

Infra-red scans done once a quarter are no match for faults that can surface and escalate within hours. What slips through those time-gaps can burn through budgets.

| Snapshot Checks | Continuous Wireless Sensing |

|---|---|

| Point-in-time only – you “see” the busbar for 3 seconds, then wait 90 days for the next visit. | Always-on view – every sensor beams an updated temperature reading every few seconds. |

| Requires shutting down panels or at least opening doors, exposing staff to live gear. | Clamp-and-go installation; sensors mount on energised busbars without service interruption. |

| Human-dependent – accuracy varies with operator skill and ambient conditions. | Automated alarms – thresholds trigger SMS / SCADA alerts via open Modbus-RS-485 the moment a joint drifts a few °C. |

| Misses slow, cumulative heating that happens between scans. | Captures micro-trends early enough for a ₹500 spanner-tighten instead of a ₹50-lakh outage. |

Continuous, wireless monitoring turns busbar health from occasional guesswork into real-time certainty—no shutdowns, no blind spots, no surprises.

🛡️ SenseLive Wireless Busbar Monitoring Suite

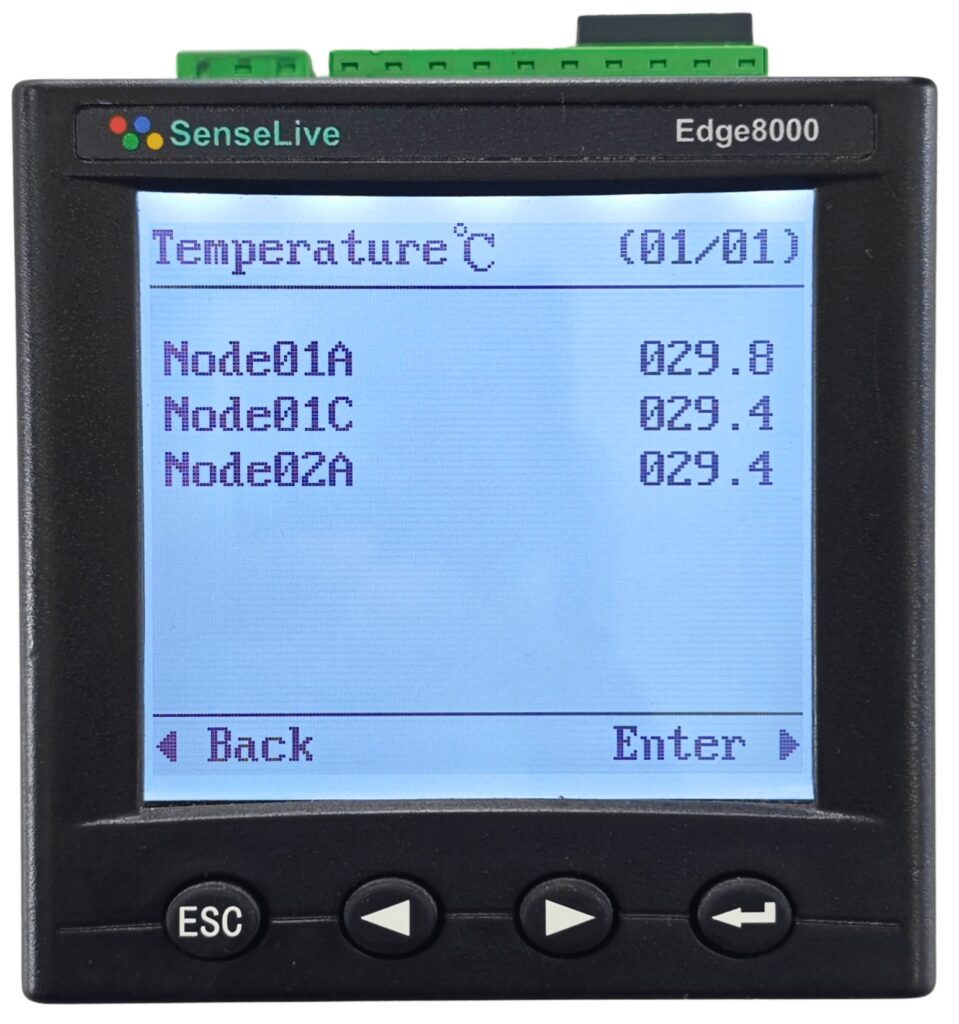

Edge8000 – The Intelligent Hub

The DIN-rail Edge8000 supervises up to 60 wireless sensors, logs energy data, and drives dual-relay outputs to trip breakers before temperatures reach danger.

SenseBT-222 – Battery-Powered Freedom

Clip-on, ultralow-power sensors broadcast accurate (±0.5 °C) readings for years on a field-replaceable cell, ideal for retrofit on live copper where wiring is impossible.

SenseCT-222 – Self-Powered Ingenuity

Harnesses the bus-conductor’s magnetic field to energise itself — no batteries, no maintenance — perfect for dense switchgear rows and OEM panel builders.

Together they create a scalable mesh that blankets every critical joint, feeder and tap-off without drilling a single hole.

🌟 Seven Reasons SenseLive Stands Apart

- True Wire-Free Installation – Sensors clamp on in minutes, no service interruption.

- Edge + Energy in One Box – Temperature and kWh on the same screen, zero middleware.

- Built-In Safety Automation – Dual relays cut power or trigger fans autonomously.

- Open Modbus-RTU Output – Plug straight into SCADA, EMS, BMS or cloud dashboards.

- Long-Life / Maintenance-Free Sensors – Battery life measured in years or harvested forever via CT.

- Scalable to 60 Points per Panel – Cover incoming mains, bus risers and critical feeders.

- Designed for Harsh Switchgear – IP-rated, dielectric housing, secure 900 MHz mesh comms (no Wi-Fi dead zones).

🏥🏬🏭 Where It Pays Off

Hospitals

Protect life-support power chains; a single prevented shutdown can save hundreds of patients and US $7k per minute.

Shopping Malls & Airports

Avoid POS chaos, tenancy SLA fines and lost footfall; retail downtime averages US $336k per hour.

Panel Builders & OEMs

Ship switchboards with embedded, value-adding IIoT monitoring, winning bids against legacy designs.senselive.io

⚙️ Deployment Roadmap

- Site Survey – Identify critical joints, feeders, risers.

- Sensor Clamp-On – Attach SenseBT-222 or SenseCT-222, bind to Edge8000 (≈1 min per point).

- SCADA / Cloud Link – Register Modbus map, set alarm thresholds, enable relays.

- Predict & Prevent – Receive mobile/SCADA alerts long before IR scans would.